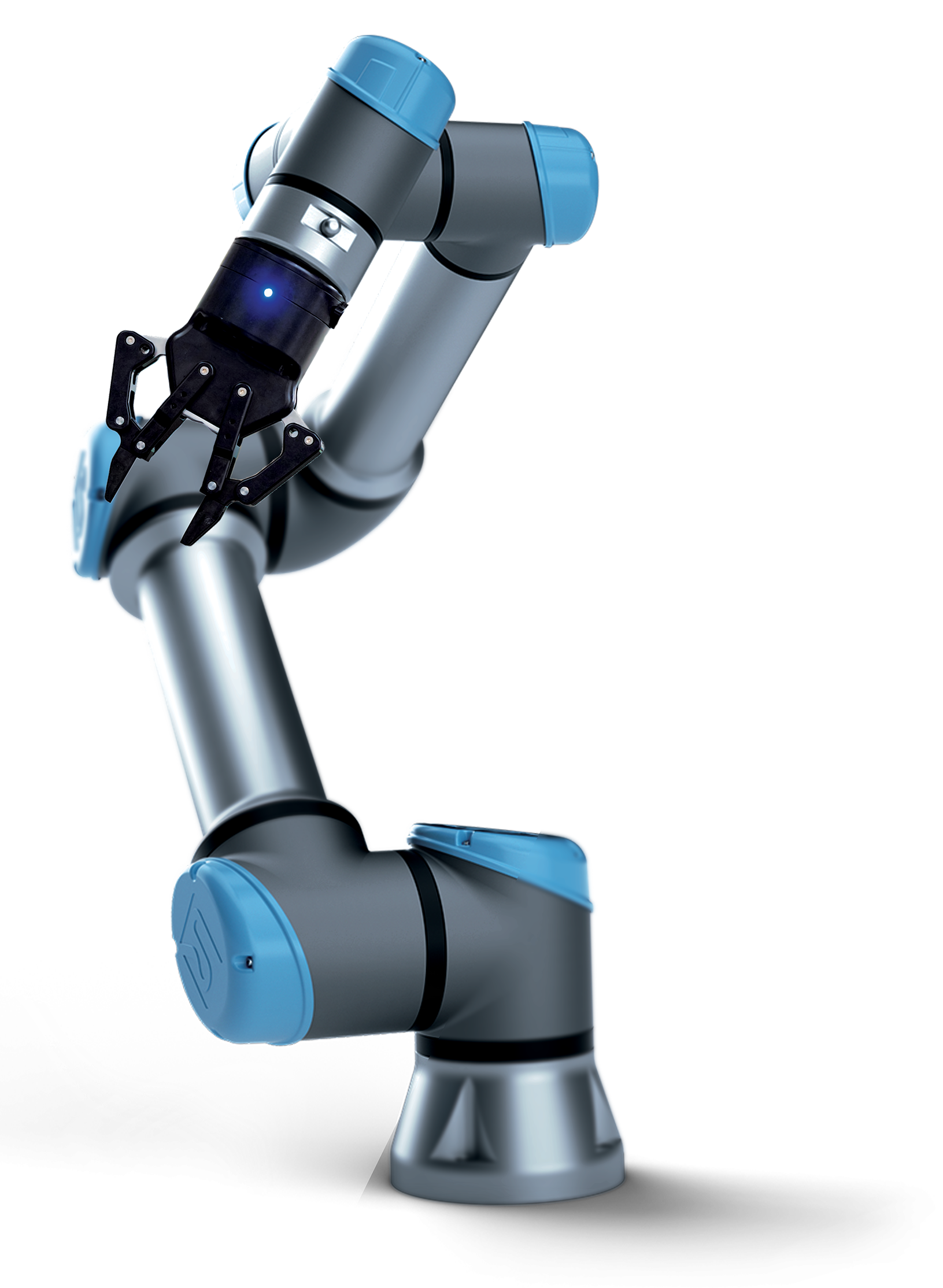

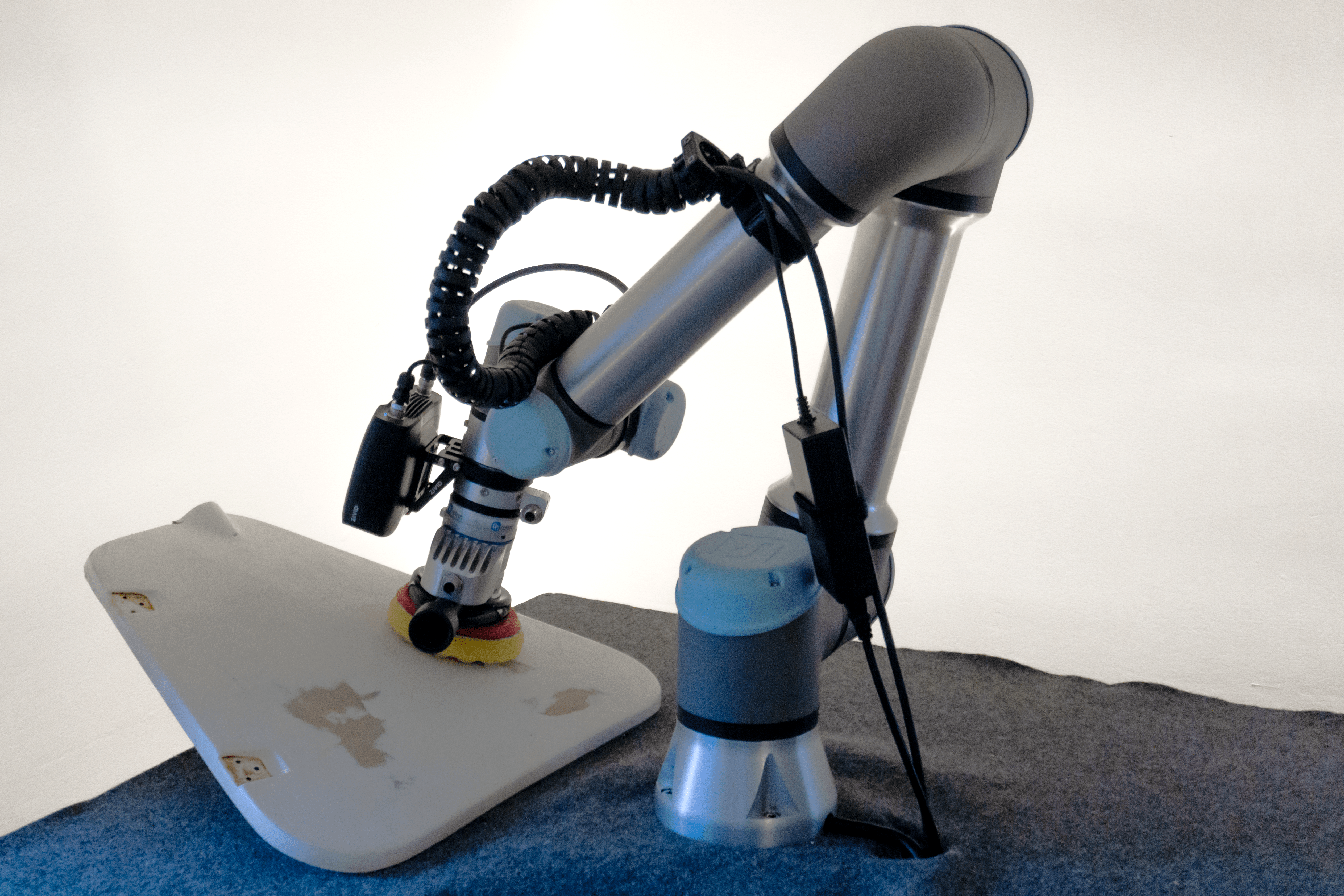

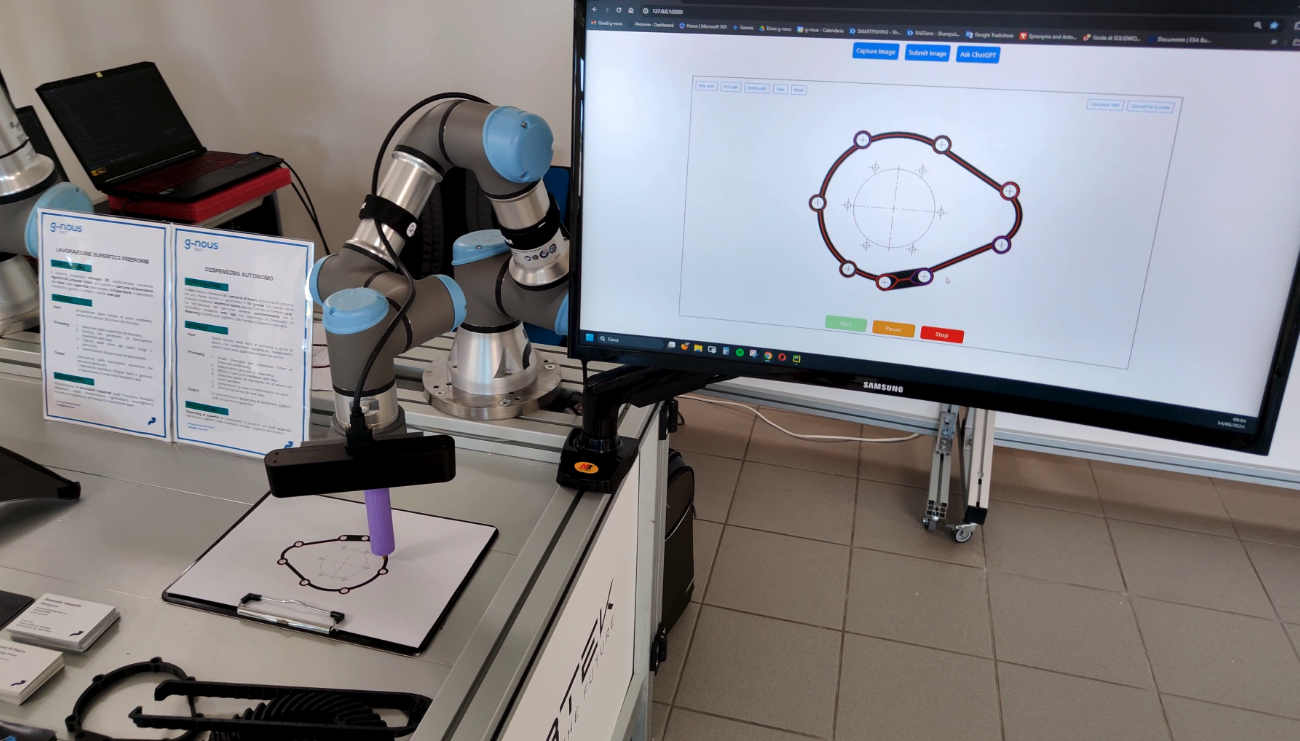

Why collaborative and smart robotics?

Across all industries, manufacturing tasks are repetitive, strenuous or even dangerous. G-nous Tech enables companies to overcome these challenges with custom solutions through collaborative robots and vision systems. We can help you to refine business processes, increase efficiency and ensure superior quality to meet the specific needs of your business by applying cutting-edge technologies, such as:

Artificial

Artificial Intelligence

Advanced

Advanced Sensing

Customised

Customised End-Effectors